Figure 4 Standalone high-resolution DLP 3D printer

Figure 4™ Standalone DLP 3D printer delivers ultra-fast additive manufacturing technology. Figure 4 delivers repeatable, true-to-CAD part accuracy in an agile, in-line manufacturing workflow.

In addition to it's ultra high speed 3D printing the Figure 4 offers a range of high performance materials for prototyping through to production, including medical grade and HT materials.

High Performance Materials

- PRO-BLK-10: True production-grade material.

- TOUGH-BLK-20: strong material with long-term UV stability for the production of black ABS-like parts.

- RUBBER-BLK: High-tear strength, malleable material for hard, rubber-like parts.

- FLEX-BLK-20: Flexible, durable material.

- ELAST-BLK is an elastomeric, black material ideal for rubber like parts.

- HI TEMP 300-AMB: Industry-leading, ultra-high temperature rigid plastic suitable for the harshest thermal environments.

- EGGSHELL-AMB 10: process-optimized material for production of sacrificial tooling for casting silicone and other materials.

- MED-AMB-10: translucent amber bio-compatible material.

- MED-WHT-10 rigid bio-compatible white material with a ceramic look and feel.

- TOUGH-GRY-10 is a high speed material for rapid design iterations providing up to 100 mm/hour build speed.

- TOUGH-GRY-15 is a strong, rigid material for production applications.

- JCST-GRN is castable green material optimized for investment casting of jewellery patterns

- New CLEAR material coming soon

Background

3D Systems’ has over 30 years of proven R&D experience and process development expertise. The production-grade materials available for Figure-4 include a broad and expanding range of materials to enable true replacement of traditional moulding and urethane casting.

Capable of digital texturing that rivals injection moulded part quality without the time and cost of tooling, Figure 4 Standalone is compatible with a variety of robust materials. Featuring a manual material feed, Figure-4 Standalone is augmented with separate post-processing units available for cleaning, drying and curing.

APPLICATIONS:

- Replacement of traditional moulding and cast urethane processes

- Rapid functional prototyping and fast concept models

- Clean and easy burnout with gypsum investments

- Grommets, seals, hoses, weather sealing, soft touch robotics, keypads, spacers, vibration dampening component parts

FEATURES:

- Non-contact membrane Digital Light Printing (DLP) technology

- Printable Build Volume (WxDxH): 124.8 x 70.2 x 196 mm

- Industry-leading 3D Sprint software for file preparation and production

- Cloud connectivity for predictive and prompt service with 3D Connect capability

- Production-grade materials

- Compact printer footprint

- Manual material feed

- Separate, manual post-curing unit, required

BENEFITS:

- Affordable initial investment

- High throughput vs. competitive 3D printing technologies

- Industrial-grade durability

- Print and use same day

- Low total cost of operations

- Application flexibility

- Efficient design iteration

- Six Sigma quality and repeatability

We Also Recommend

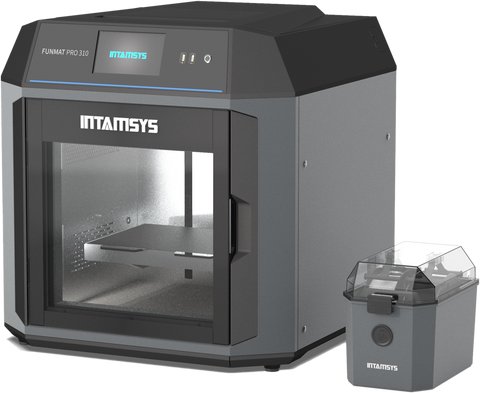

![Intamsys FUNMAT HT [Enhanced] 3D printer +PEEK ~max. 260mm * HIGH-TEMP](http://www.replik8.co.uk/cdn/shop/products/Funmat_HT_iso_large.jpg?v=1595506224)