Cimatron CAM & NC

Cimatron NC Solutions is a fully integrated CAM package for 3 to 5 axis CNC milling & turning.

Efficient Roughing

- Undertake quick and effective ultra-high volume milling on 3D stock shapes with Rough VoluMill

- Ensure short machining times for any selected machining strategy with continuously updated multi-axis stock

- Check for tool shank and holder collisions against the auto-updated stock automatically at all stages of Roughing and ReRoughing operations

- Generate a High Speed Milling (HSM) all-rounded toolpath with constant tool load, trochoidal milling, advanced clean between passes, efficient rough between layers, and state-of-the-art ridge removal

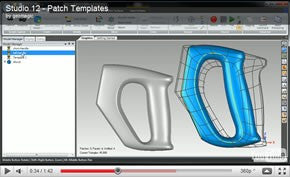

High Quality Finishing

- Choose from a rich set of 3- to 5-axis optimized machining strategies, including

- Adaptive Z layers

- True spiral motions

- All rounded motions

- Flow-line machining

- Cleanup (rest machining) and pencil

- Slope controlled finishing

- Optimized CBP (Clean between passes)

- Unique Ridges handling by Zero Overlap trochoidal

- Prevent waterfall

- Air extensions

- Uniform approach and retract

- Automatically adapt machining strategies to achieve a high, polish-free surface quality using built-in analysis of local slopes

- Benefit from highly efficient machining with any cutter combination in cleanup

Full 5-Axis Capabilities

- Reduce the need for electrodes with direct milling of narrow slots and tiny corner radiuses

- Utilize a single setup for multi-side operations

- Choose from a rich selection of machining strategies and support a complete range of cutters including tapered cutters, lollipop tools, and slot mill cutters

- Support positioning and continuous milling, providing full control over the tilt and lead angles as well as gouge and collision check of the tool shank and holder against the part

- Generate touch-of-a-button 5-axis tilting toolpaths especially suitable for rapid machining of parts with deep cavities, narrow ribs and tiny corner radiuses, using shorter and more rigid tools for best surface quality and reduced machine time

- Verify all toolpaths and eliminate unnecessary tryouts with advanced post-processor based simulation capabilities, including material removal, remaining stock, and complete machine kinematics

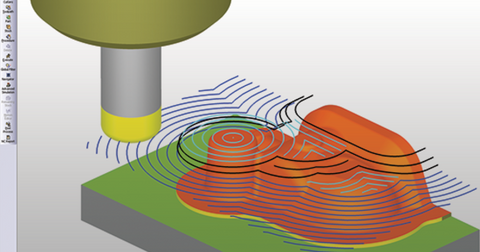

Simulation and Post-Processor Support

- View the cutting process and its results prior to machining, with a color-coded display to help analyze the remaining material around the part.

- Simulate the real machine kinematics and toolpath motion, checking tool shanks and holders against the part with advanced simulation generated with the G-code. The ability to predict machine behavior enables errors to be corrected and eliminated ahead of time

- A rich library of post-processors is offered for practically all 3-axis and 5-axis machines as well as all leading controllers

- A state-of-the-art post-processor generator can be easily customized to any specific needs

We Also Recommend